Introduction

There are many items which are daily utilized by people composed of iron like chairs, furniture, gates and other machinery. After a lifespan, the iron of machine will get rusty and require welding at any point of time in the joints of the machine.

The proposed welding management system will avail the customer in placing their order at the Welding shop to book their machine for welding. The customer can withal direct the Welding shop for any customization if he wants to do to with his machine then accordingly the staff member will work and do the welding.

The customer can provide consummate information about the size, weight, and other details of the machine thereafter he can withal book conveyor for conveying his machine at the Welding shop. The customer can additionally annex a picture of the machine so that the staff member can get a conception about the machine dimension.

The Welding shop has many staff members who are very adept in welding ergo they can weld any machine provided by the customer and additionally customize it accordingly this will avail the customer to retain his confide in the shop and ergo the system will avail in mutual understanding of both the parties.

Current System

The current system is a manual system in which the customer need to find a Welding shop in nearby nice area by physically moving in the area himself then after finding the shop he requires to convince the building person to visit his residence to have a look of the machine for welding.

This process will take much time and require physical labor of the customer and effort unnecessarily. Consequently it is very crucial to sustain a system which will be auxiliary for not only the customer but withal for the Welding shop owner to get the customer at their shop.

The system is obsolete and consequently requires an incipient system with all the working dimensions. It is not only inglorious for the customer but the shop owner additionally so require making much offered to lubricate the customer for his shop.

Proposed System

The welding management system is a required by the customer and the welding management to meet their mutual understanding and do the work within the stipulated time. The customer does not require visiting the shop himself he just needs to book an order from his account at his residence.

The Conveyor will come at the residence of the customer to hoist the machine and distribute it to the shop for welding there after completion He will convey it back to the customer’s address.

The user interface is very simple ergo does not require any prior training for the Welding shop workers as well as the customer. Both the parties can do their work without any quandary and effort. The customer can withal pay the amount through the system initially and withal he cannot afford cash on distribution option.

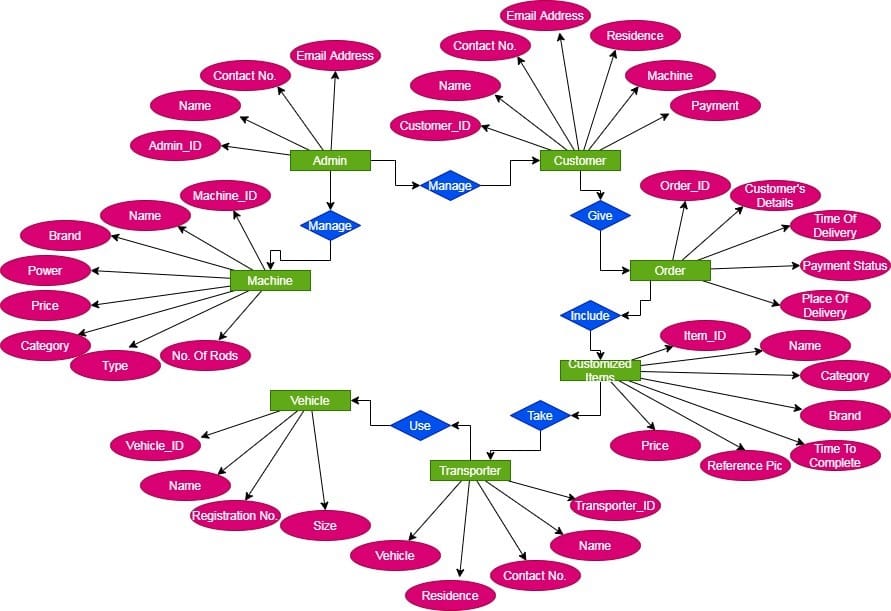

Entity Relationship Diagram

Explanation

The welding management system allows the user to initiate the process in which they can weld their machines and other equipments with the help of the welding person. This model represent the entities and their attribute which will help in sustaining the information of the system bifurcating the information in different accounts created by the users and also help in showcasing how well the data travel into the system with the help of the admin. The admin provide sustainable development while keeping an eye on each Movement in the system because this will allow him to track any error if it occurs in the system to remove it successfully. The diagram explains how briefly the entities established their relation with the attributes while sustaining the information. The attributes and their entities are defined below:

1. Admin:

The whole system is managed by the admin therefore he is solely responsible for any error if it occurs in the system. Management provides authority to more than one admin if the work load increases for a single person. This entity has the ability to access the account of other users and manipulate the information contained in it. He can also add or delete any account in the system of the users whether they are customer or employees of the company. Admin has the Supreme Power to remove any account from the database but it also needs to inform the management on prior basis. The related attributes are defined below:

- Admin_ID: A 14 digit Identity Number is attached with the account of admin randomly by the system to secure their account.

- Name: The name of each admin saved in this attribute for verification purposes as per the name suggested on the legal documents provided by him.

- Contact No.: The contact number of admin is saved in this attribute to be connected by any person at any point of time.

- Email Address: The official email address is saved in this attribute of the admin for any official query send him by the management or customer.

2. Customer:

This entity provides individual accounts to the customers who are interested in taking the services of the company. The customer first need to create an account in the system thereafter he can provide the information about the machine of which he wants to weld from the company. The information is directly sent to the consigning authority by the admin thereafter they will send the Transporter to collect the machine and pick it up to the garage. The customer can track the work done by the management with the help of the system and he can also pay the amount on priority basis estimated by the system which will showcase on the screen of the customer in his account. This entity holds the account of each customer on separate basis which will help in sustaining their individual information safety and security. The related attributes are defined below:

- Customer_ID: An identity number is attached with the customer account to bifurcate them from other accounts and save their information.

- Name: There are many customer who are attached to the system therefore it is necessary to keep the name of each customer in the system.

- Contact No.: The information about the work done is provided to the customer by their contact number which is saved in this attribute.

- Email Address: This attribute will save the email address of each customer to provide them consignment amount and bill.

- Residence: It is necessary to save the permanent address of the customer in order to pick up the machine which needs to be welded by the management.

- Machine: This attribute holds the information about the machine of the customer which needs welding.

- Payment: Information about the payment method is saved in this attribute for transparency by the management.

3. Order:

This entity holds the detail about the orders given by different customers for their particular machine which needs to be welded by the management in sustaining time. The entity creates different account of each order provided by the customer to enhance the capability and safety of the data provided by the customer and his machine. It will also save the data about the customer details and estimated time of delivery while receiving the payment status by the customer if he has paid in advance through the online mode. The customer can also offer for cash on delivery option in which the customer can pay the amount at the time of delivery of his machine. The related attributes are defined below:

- Order_ID: Every order is unique and provided by different customer therefore it is necessary to attach an Identity Number by the system.

- Customer’s Details: This attribute holds the detail about the customer who has provided a particular order for the machine which needs to be welding.

- Time of Delivery: The management provide an estimated time of delivery to the customer after analyzing the machine for welding.

- Payment Status: This attribute hold the status of the payment if it is done by the customer priory through online mode or he has opted for cash on delivery option.

- Place of Delivery: It is necessary to save the data about the place of delivery therefore the management can provide this information to the Transporter.

4. Customized Items:

The customer has different machines and items which are made up of iron and helpful for day to day life of the customer. due to time and rust, the iron will get weaker and rusty which needs to be weld again from the joints provided in that particular item. The items are of different size and weights which are predefined by the customer while providing the information to the management about the item which needs to be weld therefore the management will decide whether they need to carry the item to the shop or else the customer has to lift it on his own. This entity holds the information about the customized items used by the customer since long time and now it needs repair to be used again. The related attributes are defined below:

- Item_ID: Every item is attached with an identity number provided by the system to categories their information in different accounts.

- Name: This attribute holds the information about the name of the item which needed welding provided by the customer.

- Category: It is necessary to get an idea of the category to which the particular customer is atom belongs which help in welding by the staff.

- Brand: This attribute will save the information about the brand to which the item belong in order to get the information about the joints which need welding

- Time to Complete: The management provides an estimated time to complete the welding of the machine provided by the customer which is saved in this attribute.

- Reference Pic: To get an idea about the item, the staff will collect reference pick from the customer of the machine which needed welding.

- Price: It is very important to get an idea about the price of the item which needs repairing given by the customer.

5. Transporter:

The person who is responsible for the transportation of the machine belongs to the customer is the Transporter. He lifts up the machine from the residence of the customer and delivers it to the Welding shop. This entity allows the Transporter to create their individual account and save their personal data in it they can Store their personal information along with the work related data. The management provides information of the customer to the account of Transporter thereafter he will proceed to the residence of the customer after getting the information of the machine to be taken for delivery at the Welding shop. The Transporter can also get salary and leave policy through his account. The related attributes are defined below:

- Transporter_ID: The system attaches The Identity Number with the Transporter to sustain their personal information in the account.

- Name: There is more than one Transporter attached with the system therefore the name should be filled in this attribute.

- Contact No.: To provide the information about the customer’s machine, the Transporter contact name should be saved in this attribute.

- Residence: It is necessary to save the permanent address of the Transporter for verification and authentication purpose.

- Vehicle: The Transporter uses a particular vehicle for delivery which information needs to be saved in this attribute.

- Machine:

There are many types of machine which are used by the customer which comes in different type and size and of different brand according to the requirement produced by the customer. The customer can also customize a particular machine which is made up of iron through the method of welding. After a particular time, every item which is made up of iron will get Rusty and require welding at a particular time. this entity save the information about the different type of Machines which needed welding by the customer and also help in saving the information related to the particular machine provided by the customer. The related attributes are defined below:

- Machine_ID: Every machine is equipped with an identity number provided by the system to separate their information.

- Name: This attribute who is the name of the machine which needed welding provided by the customer.

- Brand: Every machine belongs to a particular brand which name is saved in this attribute.

- Power: The amount of power consumed by the machine in a particular time period is saved in this attribute.

- Price: The price in which the customer has purchased a particular machine that information is saved in this attribute.

- Category: Every machine belongs to a particular category depending upon the work in which it is used which is saved in this attribute.

- Type: The type of the machine according to the work and requirement provided by the customer.

- of Rods: This attribute holds the information about the number of rods which is needed to weld a particular machine.

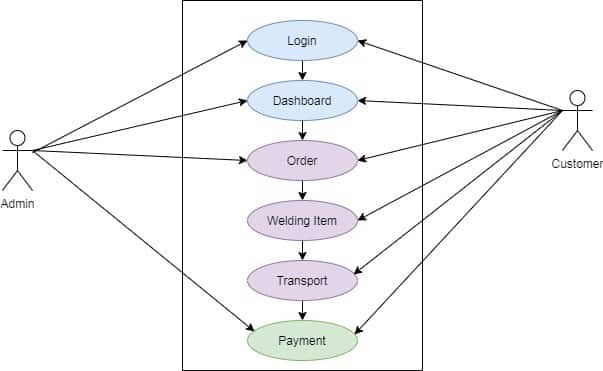

User Interface Model:

Login:

The building management system is a unique system which will help the customer in welding there customized machines which will get rusty due to time and water. Therefore, the interface should be capable enough to handle all the queries of the customer along with the management of the shop. The user interface is created in a simple way in which the user will get login page as their first display after holding the option of forgot password and new user registration.

Dashboard:

The dashboard contains option related to the user depending upon the type of the user who has access to the account. The options are customized by the management at any point of time according to the need raised by the particular user. The dashboard contains different option for different user according to the authority provided to them as per their skill set. The user interface is humble and error-free that will help the people who are using it.

Order:

The user interface of the customer will allow him to raise an order providing the information about the machine which he needs to weld after that this order will authorized by the admin and send it to the welding staff thereafter they will decide whether the customer has choose an option for transporting the machine by the Transporter or else he can transport the machine on his own at the Welding shop.

Welding Item:

The customer will provide a brief description about the machine which he needs to weld by providing the information about the size, weight, brand and type of the machine ne he needs to be weld. This information will be helpful for the staff member there were provided to them by the system user interface to get knowledge about the item’s dimensions. The interface may also submit the history of the same item if the customer has used the particular item for welding in previous time.

Transport:

The user interface allows the customer to provide the information about the item dimension after that the staff member will get an idea whether the item required transportation of big vehicle by the Transporter or else the customer can transport the machine on his own at the Welding shop. This information will be provided by the customer at the time of order he has raised from his account. This information will be transferred to the Transporter if the item requires transportation by a skillful person. Thereafter, it is the responsibility of the transport to transport the item safely and securely at the warehouse for welding.

Payment:

The user interface allows the customer to get an idea about the estimated amount which will be charged by him for the welding done by the shop. the interface provide option to the customer whether he wants to pay the price initially through online mode by the help of his account or else he opted for cash on delivery option so that the Transporter will collect the amount when he reaches the address of the customer for delivery of the final product after welding.

can i get this project ?